7. Responsible supply chain

7.1 Description of the supply chain

For a company like Madrileña Red de Gas, the pillars of its business purpose are:

- the extension of the distribution network and its safe maintenance, including satellite plants, and

- the operation in the distribution network with all the services that this entails.

The contracting of service companies for the set of processes that make up its value chain is a key element. The correct management of the supply chain is a clearly relevant aspect for sustainability at MRG.

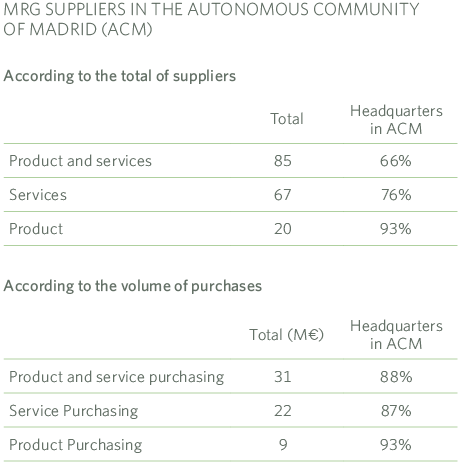

80% of purchases are made with 18 suppliers, of which sixteen are service suppliers, one is a service and product supplier and the last one is a product supplier.

The main item in the purchase of services is the construction and maintenance of the network, in line with the above. In this case, the estimated impact of labour is 80%. We can only achieve our commitments to the environment, quality and safety if they are correctly passed on to our suppliers.

As regards the purchase of products, the main item is liquefied petroleum gas for LPG satellite plants. The estimated impact of labour on product purchases is 30%.

Significant transactions for MRG are those exceeding 20,000 euros per year. Within the significant purchases throughout 2020, 88% have been from local suppliers, i.e. suppliers from the Autonomous Community of Madrid.

No new outsourcing processes were carried out during 2020, nor did we have any major changes in our supply chain.

7.2 We minimize risk in a transparet process

At Madrileña Red de Gas we have established a management system that standardizes the purchasing processes, ensuring: the transmission of the required standards in terms of quality, environment, safety and commitment to the 2030 objectives.

We promote the maintenance of long-term relationships of trust with suppliers, establishing objective and impartial selection mechanisms, always ensuring compliance with the principles established in our Code of Ethics.

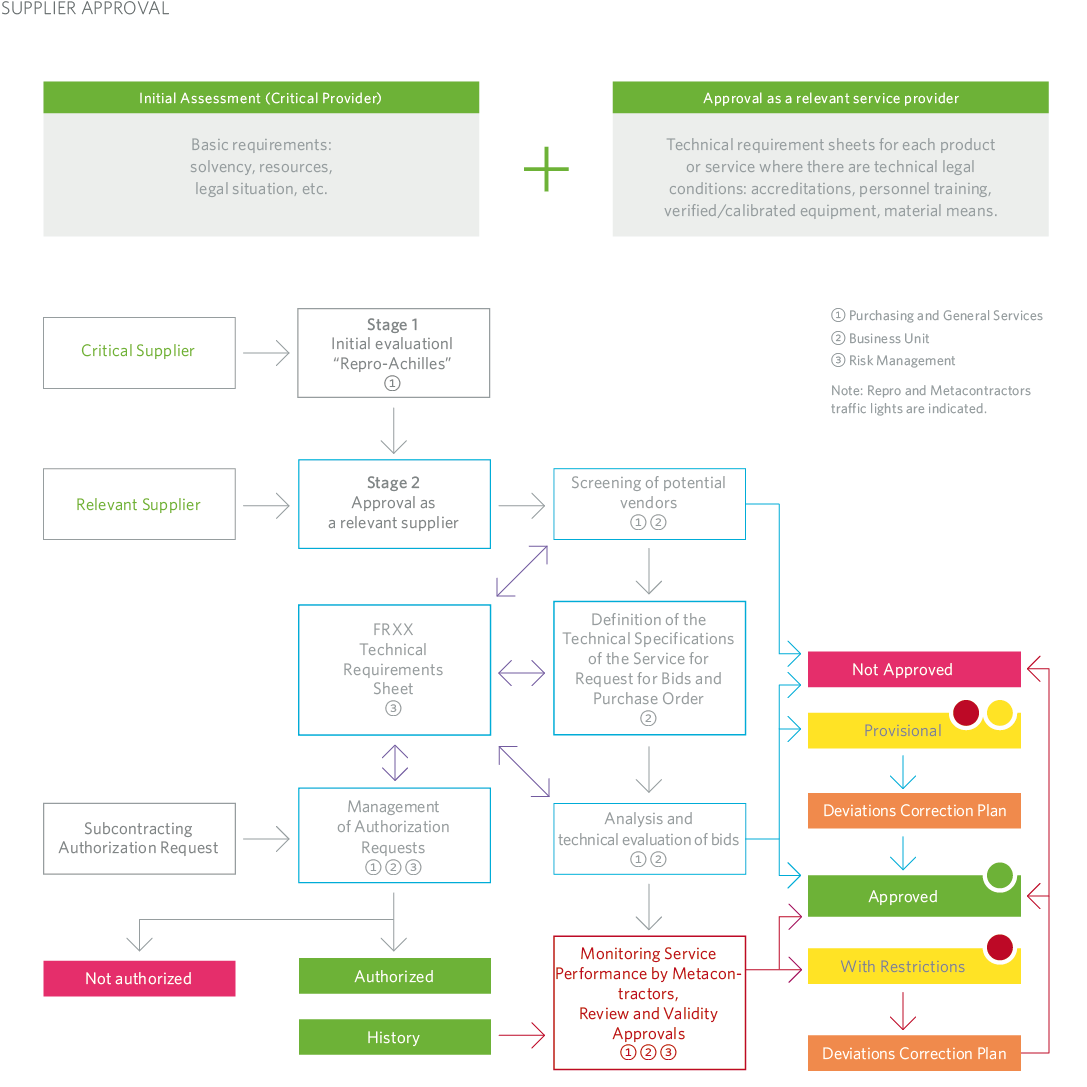

The starting point to be able to deal correctly with purchasing processes is to have a set of approved suppliers. For this it is important to distinguish two key elements for us. Firstly, we identify critical suppliers, understanding as such those that provide us with a product or a key service in our value chain (construction, network maintenance, periodic inspection, home operations, polyethylene pipe manufacturers, etc.), and secondly we add the concept of relevant services, being services that are highly susceptible to quality criteria as they require compliance with legal technical requirements. For these services we establish and always keep our requirement sheets and the requirements included in our approval procedure up to date, ensuring that they are always in line with legal compliance.

The technical-legal nature of the requirements includes the qualifications of the personnel who are to carry out the work. We also have an approval process for the personnel of the service companies, in order to ensure the necessary training and qualifications.

Through the Supplier Qualification Service, MRG obtains the information that allows us to carry out the initial evaluation for the approval of critical suppliers. With regard to approval as a relevant service provider, this also involves assessing the documentation to be provided by the supplier in accordance with the requirements of the service it can provide.

The approval process is fed back through the monitoring of suppliers’ performance during the contracts. As part of the approval review process, surveys are carried out to gather feedback from the units on the service provided.

Purchasing or contracting needs are planned and budgeted by the business or corporate units and managed by Purchasing. From Purchasing we integrate needs, if possible, increasing efficiency in the process and improving purchasing conditions.

The units together with the requirements draw up the technical requirements specification, which in the relevant services will take into account the corresponding specification sheets. Once the information is available and only with the approved suppliers for the corresponding services / products, the contracting process can be carried out.

Purchasing Process:

- Single specification and rules for all participants.

- Three or more bidders are invited.

- It is carried out through the same communication medium.

- A single delivery time is defined.

As a general criterion, bids are requested from at least three companies, being compulsory when the budget is over 20,000 euros. For bids in excess of 100,000 euros, a tender opening committee is set up with the participation of the requesting unit, guaranteeing the transparency of the process at all times. At the proposal of the requesting Unit or the Department of Legal Services, a lawyer may also attend the tender-opening ceremony in procedures deemed necessary.

Once the tenders have been awarded, the contract documents are drawn up and signed. The legal department reviews and validates contracts, ensuring legal compliance with all contract terms and conditions. In general, contracts may not be for a period of more than three years. The quality, environmental and operational safety requirements are part of the contract documents and must therefore be complied with by the supplier. Likewise, the penalty clauses on legislative compliance and criminal liability are also annexed; in the contracts they are required to comply with legislation at all levels, labour (ORP, insurance contributions, compulsory training for the activity, etc.) and business (compliance with the tax authorities, operational accreditations, etc.), in accordance with our code of ethics, anti-corruption policies and principles.

Accessions to the public offering:

The regulated nature of our business includes specific public incentives for the natural gas sector, such as accessions to the public offer. The management of services for the connection of new supply points by means of a public offer consists of the publication of prices and conditions established for the distributor (in this case MRG) and type of market, to which the interested installation companies adhere.

During 2020 in Madrileña Red de Gas we have maintained our public offer and commercial campaigns as a sign of loyalty and commitment to our most traditional channel: the installation companies and the associations that represent them in Madrid, AGREMIA.

In line with previous years, more than 300 installation companies have signed up to Madrileña Red de Gas 2020 Public Offer to obtain commercial benefits for installations carried out in their distribution area. In addition, we have incorporated 8 new companies to our network of autorised distributors all over the community of Madrid.

7.3 Communication and collaboration to achieve common goals

At Madrileña Red de Gas we understand that the demand for compliance with the requirements must be accompanied by a relationship with suppliers that allows us to share objectives and commitments. If our suppliers share our vision and are not just bound by contract obligations, it will be much easier to move forward and meet sustainability goals.

There are several mechanisms that we develop and use in this regard:

- We maintain fluid communication with our suppliers, discussing with them the possible problems or difficulties in the contracts that are in force, jointly looking for improvement actions, and sharing work plans.

- We have implemented the Supplier Document Monitoring Service. On the tool we manage two fundamental elements in the relationship:

- In it our suppliers must keep updated all the information corresponding to the requirements of the service or services they are providing (as a company, their staff, equipment and materials). Through a traffic light code, suppliers can see if everything is correct or not and the deadlines for updating documents. In addition, the tool automatically sends reminders via e-mail for missing, expiring or incorrect documents.

We must highlight the operational control visits, in which the technicians who carry out the supervision visits, proceed to monitor the documentation provided through the tool.

- We share prevention, industrial safety andenvironmental documentation with MRG employees and with the main contractors through a virtual tool.

- In it our suppliers must keep updated all the information corresponding to the requirements of the service or services they are providing (as a company, their staff, equipment and materials). Through a traffic light code, suppliers can see if everything is correct or not and the deadlines for updating documents. In addition, the tool automatically sends reminders via e-mail for missing, expiring or incorrect documents.

- We have implemented during 2020 on the digital process management tool of the Integrated Management System the participation of suppliers in the incorporation of information for the control of the processes in which they participate.

- We share lessons learned from incidents or accidents detected during operational control visits, and at MRG we work to understand the causes and seek solutions that allow us to move towards compliance with our commitments.

- During 2020, a major outreach and communication effort was conducted among contractor companies related to pandemic issues, focused on ensuring the greatest pandemic safety for contractor personnel. The following actions are highlighted:

- Dissemination of the protocols of action of the Occupational Risk Prevention Services against exposure to SARS-Cov2 among those responsible for prevention in contractor companies.

- Request for annexes to the Health and Safety Plans on site, including safety measures against coronavirus.

- Campaigns that boosted the search for possible vulnerable personnel for covid according to the protocol discussed above.

- Promotion of training/information of contractor personnel in safety measures against coronavirus.

- Biohazard risk assessment for coronavirus exposure

- COVID-19 Coronavirus Action Protocol